It is no lie that our planet is suffering from plastic waste. What are we going to do to stop this and preserve our planet for generations to come? On world environment day we thought we’d show what Parvalux is doing to be more aware of our plastic waste and to be more than just carbon neutral.

2023 World Environment Day Campaign

This year the world environment day campaign is #BeatPlasticPollution so what is Parvalux doing to stop our plastic waste?

With the adoption of 6S within our manufacturing processes we are becoming more efficient with time and material utilization, although we do not use a lot of plastic, if we do generate any waste, it is important to us that we send the material to recycling, not placing it in general waste, keeping it out of landfills so the material can be reused. This is not just for plastic; we are identifying as many waste streams as we possibly can to stop materials going to landfill.

Being able to recycle instead of just putting plastic in general waste means that we reduce the need to harvest new raw materials, saves energy and will reduce greenhouse gas emissions that contribute towards climate change. The head of QHSE Brian Roche has said “At Parvalux we are hugely supportive of World Environment Day which reminds us all of the continuing efforts needed by every one of us to do what we can to reduce CO2 emissions and ensure we operate in an environmental sustainable manner. I am very proud of our the carbon reductions our new premises will bring and our continuing journey to improve for years to come.”

Parvalux’s Renewable Energy

Parvalux’s Renewable Energy

Talking about climate change, Parvalux is also going to be Reducing our usage of energy from the national grid by creating our own renewable energy.

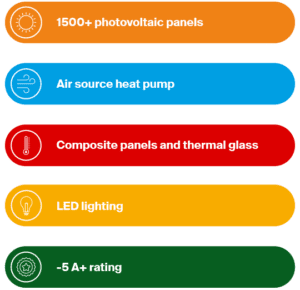

We will be doing this at our new factory which we will be moving into very soon! We have over 1500 PV panels on the rooftop of our new factory, this will produce 100% of the building’s operational power we are expected to use! This energy created by the solar panels will feed our lights, lifts, and office PCs; The excess energy will go into our electric car charging points and E-bike charging points to help encourage staff to use cleaner methods of transport into work. By creating our own renewable energy, we can cut our carbon footprint by over 340 tons of CO2 per year.

At the new factory, Parvalux will also be using heat pumps to provide the building with sustainable heating and hot water which will further our reduction in CO2 emissions and help to reduce our scope 1 emissions.

Sustainable Development Goals

Parvalux will be achieving many sustainable goals this year as we move into our new factory which has been built with energy-efficient materials that are also sustainable.

7000 tonnes of bricks and concrete were recycled from the sites existing structures for the new building’s subbase. Panels for the building were cut to the correct size to eliminate on-site waste. The panels were chosen based on their excellent thermal performance which is an important component in insulation and management of internal temperature. The panels feature a hybrid insulation core which is HCFC, CFC and HFC-free. The glass panels on the building are fitted with efficient heat retention and energy performance blended into the design to give the building a visually stunning and modern look while creating an impressive working environment for our staff. This will allow us to use less of air-conditioning units which will save the renewable energy we have created. Achieving a low environmental impact was the goal of the build of the new factory and we believe we have done that by reducing the amount of scope 1 and scope 2 emissions we create.

Parvalux doesn’t want to stop there! We believe that when we develop and expand our factory, we will also need to increase our renewable energy gains as well to ensure we remain better than carbon natural. Also, as technology improves with electric cars and as more staff depend on this method of transport to get to work, we will continue to expand the amount of electric car charging points that we have on-site.

Campaigns and Initiatives

Parvalux is always looking to find new ways that can help to reduce the CO2 we produce and that is why with our new factory we are introducing a car share scheme that will reward staff who pick up other colleagues on their way into work. In doing this it will help to reduce the CO2 emissions our staff will release into the atmosphere and therefore taking even better care of our environment. With access to a pool of Parvalux bikes, Beryl bikes and scooters some of our staff members won’t be realizing any emissions into the atmosphere on their way to work.

It is very important that we try our best to keep our planet’s environment clean and safe for wildlife and for future generations to come. That is why Parvalux is trying everything we can to reduce the amount of plastic we throw away. Not only are we reducing our waste, but we are also reducing the amount of CO2 emissions we release into the atmosphere by producing our own energy we will use at our new factory. By also providing incentives to staff to use greener and cleaner travel into the workplace we are taking the necessary steps as a company to protect our planet and enable our growth without damaging the environment. Parvalux will continue to look at ways to reduce waste and emissions that are released into the atmosphere to set an example for many other companies and businesses in the local area to do the same.

Use the hashtag #BeatPlasticPollution to show how you are working towards a greener and cleaner workplace.